Blog

Envisioning Tomorrow: The Rise of Best Rigid Flex PCB in Modern Electronics

As the demand for more compact and efficient electronic devices continues to soar, the adoption of advanced technologies like rigid flex PCBs has emerged as a game-changer in the industry. According to a recent report by MarketsandMarkets, the rigid flex PCB market is expected to grow at a CAGR of 8.3%, reaching $6.15 billion by 2025. This growth is driven by the increasing need for lightweight, space-saving solutions across various sectors, including consumer electronics, automotive, and medical industries. The integration of rigid flex PCBs not only enhances the performance and durability of modern electronics but also reduces the overall cost of repair and maintenance, making them an attractive option for manufacturers. With their unique ability to combine flexibility with the strength of rigid boards, rigid flex PCBs are paving the way for innovative designs that promise efficiency and reliability in tomorrow's technological landscape.

The Growing Demand for Rigid-Flex PCBs in Consumer Electronics: Key Statistics and Trends

The demand for rigid-flex printed circuit boards (PCBs) is surging in the consumer electronics market, driven by the need for lightweight, compact designs that maximize performance. According to a recent report by MarketsandMarkets, the global rigid-flex PCB market is anticipated to reach $2.66 billion by 2024, growing at a CAGR of 6.14% from 2019. This growth is fueled by the increasing adoption of mobile devices, medical equipment, and military applications, where reliability and durability are paramount.

In particular, the smartphone industry has been a key driver, accounting for about 45% of the total rigid-flex PCB market share in 2023. With manufacturers striving to create sleeker devices and integrate more functionality into limited space, the versatility of rigid-flex PCBs makes them an ideal choice. Their ability to withstand high stress and minimize interconnections further enhances signal integrity and decreases the likelihood of failure, making them increasingly popular among engineers and designers focused on innovation in consumer electronics. As consumer preferences shift toward more complex yet compact products, the adoption of rigid-flex technology is set to redefine modern electronics.

Addressing Design Challenges: Common Issues Faced with Rigid-Flex PCBs

In the rapidly evolving landscape of modern electronics, rigid-flex PCBs have emerged as a critical component, addressing design challenges while allowing for greater flexibility and space efficiency. The global flexible printed circuit board market size was valued at approximately $28 billion in 2022 and is projected to grow significantly, driven by applications in automotive, consumer electronics, and medical devices. Rigid-flex PCBs, known for their multilayer design, are particularly prominent in sectors requiring lightweight solutions and complex circuitry, such as aerospace and military applications, where reliability is paramount.

When designing high-precision temperature sensing circuits, such as those with an accuracy of ±0.1°C, engineers face various challenges associated with thermal, electrical, and mechanical factors. For instance, the thermal management of rigid-flex configurations necessitates careful consideration of material choices and layout to ensure optimal performance. Additionally, the integration of wearable temperature sensors demands robust design strategies to mitigate interference and enhance signal integrity. By leveraging advanced simulation tools and design methodologies, engineers can effectively navigate these common issues and harness the potential of rigid-flex PCBs for innovative applications across multiple industries.

Manufacturing Complexities of Rigid-Flex PCBs: Insights into Quality Control and Reliability

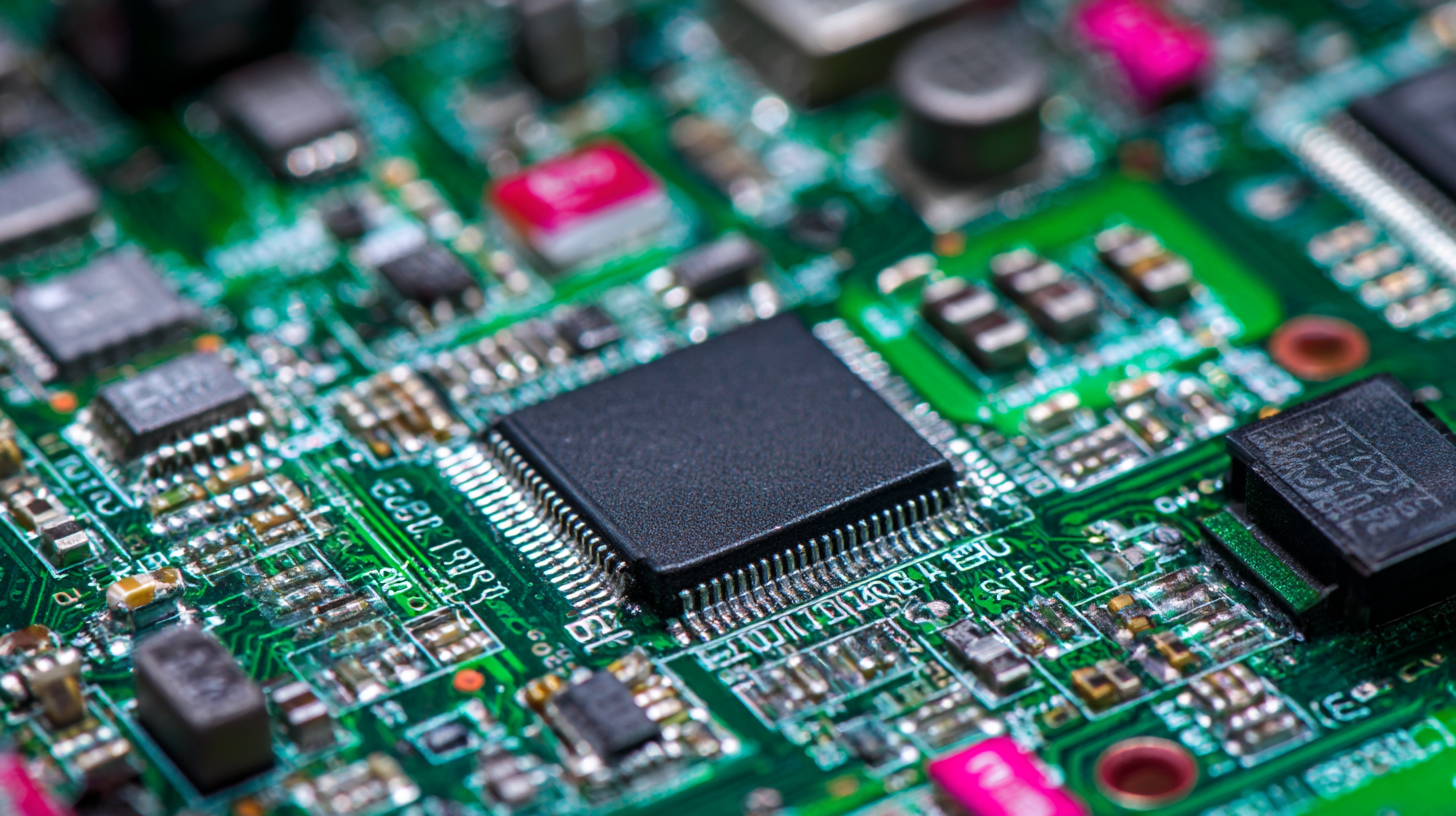

The manufacturing of rigid-flex PCBs presents unique challenges that directly impact quality control and reliability. Unlike traditional circuit boards, rigid-flex designs integrate both rigid and flexible substrates, necessitating precise alignment and layering during production. Any misalignment can lead to circuit failures, making rigorous quality assurance protocols essential. Implementing automated inspection systems can greatly enhance the detection of defects early in the process, ensuring higher reliability in the final product.

The manufacturing of rigid-flex PCBs presents unique challenges that directly impact quality control and reliability. Unlike traditional circuit boards, rigid-flex designs integrate both rigid and flexible substrates, necessitating precise alignment and layering during production. Any misalignment can lead to circuit failures, making rigorous quality assurance protocols essential. Implementing automated inspection systems can greatly enhance the detection of defects early in the process, ensuring higher reliability in the final product.

Tip: Establish a robust training program for your manufacturing team, focusing on the specific requirements of rigid-flex PCB production. This can empower your workforce with the knowledge to identify potential issues before they escalate, thus maintaining the integrity of the manufacturing process.

Furthermore, the adhesives used in bonding the different substrates play a pivotal role in the longevity and performance of rigid-flex boards. Selecting the right adhesive that can withstand thermal cycling and environmental stresses is crucial. Consistent monitoring of adhesive application techniques can prevent delamination and enhance the mechanical properties of the final assembly.

Tip: Regularly test the adhesion properties through accelerated life testing to predict long-term reliability. This proactive approach will ensure that the PCB can endure the operational conditions it will face in real-world applications.

The Cost-Benefit Analysis: Rigid-Flex PCB vs. Traditional PCBs in Modern Applications

In the rapidly evolving landscape of modern electronics, the cost-benefit analysis of rigid-flex PCBs versus traditional rigid and flexible PCBs reveals significant advantages for the former. Rigid-flex PCBs combine the best attributes of both types, offering enhanced design flexibility, reduced space requirements, and improved durability. This technological innovation streamlines complex assemblies, minimizing the number of required interconnections and ultimately leading to lighter, smaller products without compromising performance.

When evaluating costs, it's essential to consider not only the initial manufacturing expenses but also the long-term benefits. Rigid-flex PCBs can reduce assembly time and labor costs due to their integrated design, which limits the need for separate components and connections. Additionally, the improved reliability of these PCBs tends to result in lower failure rates and maintenance costs over time. For manufacturers aiming to stay competitive while delivering innovative products, investing in rigid-flex PCB technology proves to be a prudent strategy that balances upfront expenses with substantial operational savings in the long run.

Future Trends in Rigid-Flex PCB Technology: Innovations Shaping the Electronics Landscape

The rapid growth of Rigid-Flex PCB technology is reshaping the electronics landscape, driven by continuous innovations and increasing adoption across various industries. The market for Flex Printed Circuits (FPC) is poised for significant expansion, with the flexible printed circuit antenna market alone valued at $250 million in 2022 and projected to reach $410 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.2%. This trend is further complemented by the overall growth within the PCB assembly market, which is seeing an influx of new technologies and increased demand across automotive, consumer electronics, aerospace, and medical applications.

As the electronics sector evolves, Rigid-Flex PCBs—combining the benefits of both rigid and flexible circuit boards—are becoming essential for the development of compact and lightweight electronic devices. With applications spanning from military equipment to advanced medical devices, the market is expected to reach $3.5 billion by 2032, growing at a CAGR of 5.25%. This trend highlights the crucial role of Rigid-Flex PCB technology in meeting the ever-increasing demands for efficiency, performance, and miniaturization in modern electronics.

Envisioning Tomorrow: The Rise of Best Rigid Flex PCB in Modern Electronics

| Application Area | Innovative Features | Market Growth Rate (%) | Key Drivers | Challenges |

|---|---|---|---|---|

| Telecommunications | High density and compact design | 12 | 5G adoption, miniaturization | Complex manufacturing process |

| Consumer Electronics | Lightweight and flexible design | 15 | Increased demand for smartphones and wearables | Cost constraints |

| Automotive | Enhanced durability and reliability | 10 | Electrification of vehicles, smart features | Regulatory compliance |

| Medical Devices | Biocompatibility and precision engineering | 8 | Aging population, technological advancement | High development costs |