Blog

Why PCB Make is Essential for Your Electronics Projects: Unlocking Innovation

In today's fast-paced electronics industry, the importance of efficient and innovative PCB make processes cannot be overstated. As the backbone of modern electronic devices, printed circuit boards (PCBs) are intricately woven into the fabric of technology, playing a critical role in everything from smartphones to sophisticated industrial machinery. According to a recent industry report by Research and Markets, the global PCB market is projected to reach $81.05 billion by 2025, growing at a CAGR of 4.5%. This growth underscores the necessity for manufacturers and designers to prioritize effective PCB make strategies to stay competitive and meet consumers' evolving demands.

The shift towards miniaturization and increased functionality in electronics has further amplified the need for advanced PCB make techniques. With the rising complexity of circuits and the incorporation of cutting-edge materials, businesses are beginning to explore innovative manufacturing methods that not only enhance performance but also reduce costs. A well-executed PCB make can lead to significant improvements in device reliability, efficiency, and lifespan. In this context, embracing cutting-edge technologies and practices in PCB manufacturing is essential for unlocking innovation and ensuring the success of upcoming electronic projects, ultimately shaping the future of the industry.

The Critical Role of PCB in Modern Electronics Development

In modern electronics development, the significance of PCB (Printed Circuit Board) cannot be overstated. The intricacy involved in PCB design forms the backbone of today’s innovative electronics. As highlighted in recent industry insights, a skilled designer with over 18 years of experience emphasizes that meticulous attention to detail and craftsmanship in PCB design directly translates into the quality and reliability of electronic products. This emphasis on design is crucial as it lays the foundation for the performance of the entire electronic system.

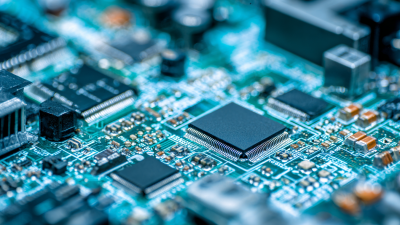

Tips: When embarking on an electronics project, always prioritize efficient PCB design by ensuring that your layout is optimized for both size and function. Additionally, consider the materials used in PCB creation. Advanced materials can significantly enhance conductivity and performance, a factor that is increasingly essential with the rise of technologies like 5G.

Moreover, the growing demand for high-performance PCBs aligns with the expanding market for electronic components. The latest trends show that the PCB industry is projected to reach substantial market sizes in the coming years, driven by technological advancements. Innovators working on electronics projects today must leverage PCB technology to stay competitive and push the boundaries of what is possible in electronics.

Understanding the Types of PCBs: Flex, Rigid, and Rigid-Flex

When it comes to electronics projects, understanding the types of

printed circuit boards (PCBs)

is crucial, as each type serves unique purposes and applications.

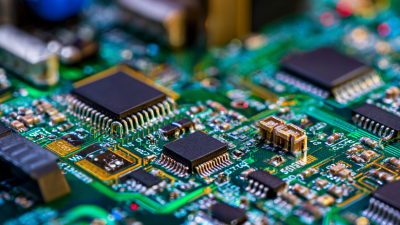

Rigid PCBs are the most common type and are characterized by their solid construction.

They provide a stable platform for components and can support complex circuitry designs, making them ideal

for consumer electronics, automotive applications, and industrial machinery.

Their robust nature allows them to withstand environmental stresses, which is essential in ensuring the

longevity and reliability of electronic devices.

On the other hand,

Flex PCBs offer unparalleled versatility as they can bend and twist to fit into confined spaces.

This flexibility makes them perfect for wearable technology and compact

electronic devices, where space is a premium. They allow for innovative designs that can adapt to the user’s

movements, ushering in new possibilities for product functionality.

Lastly, rigid-flex PCBs combine the best features of both rigid and flex boards, enabling designers

to create intricate layouts that are both compact and expandable. This adaptability is particularly beneficial in

aerospace and medical devices, where reliability and

space efficiency are paramount. Understanding these

different types of PCBs empowers engineers and designers to unlock innovative solutions in their electronic projects.

Industry Growth Trends: The PCB Market Expected to Reach $85 Billion by 2026

The printed circuit board (PCB) industry is poised for remarkable growth, with projections indicating that the market will soar to $85 billion by 2026. This growth is driven by several factors, including the increasing demand for consumer electronics, the rise of IoT devices, and the expansion of electric vehicles. As the complexity of electronic systems increases, so does the need for advanced PCBs that support higher functionality and reliability. Manufacturers are thus challenged to innovate continuously to keep pace with these evolving demands.

Moreover, the rise of smart technologies and automation has led to a surge in PCB applications across various sectors, including healthcare, telecommunications, and automation. Companies investing in PCB technologies are not only addressing the pressing needs of today’s market but are also setting the stage for future advancements. As industries embrace digital transformation, the role of PCB in enabling sophisticated electronic designs becomes more crucial, underscoring its significance in driving innovation and sustainability in electronics projects.

Why PCB Make is Essential for Your Electronics Projects: Unlocking Innovation - Industry Growth Trends: The PCB Market Expected to Reach $85 Billion by 2026

| Year | Market Size (Billion USD) | Growth Rate (%) | Key Innovations | Regional Demand |

|---|---|---|---|---|

| 2022 | 60 | 4.5 | Flexible PCBs, Multi-layer PCBs | Asia-Pacific, North America |

| 2023 | 65 | 8.3 | HDI PCBs, Rigid-Flex PCBs | Europe, Asia-Pacific |

| 2024 | 72 | 10.8 | Nano-coating Technologies | North America, Latin America |

| 2025 | 78 | 8.3 | Integration of AI in Design | Middle East, Asia-Pacific |

| 2026 | 85 | 8.2 | Smart PCB Technology | Global, with rising demand in Emerging Markets |

Cost Efficiency: How Custom PCBs Can Minimize Production Expenses

The incorporation of custom printed circuit boards (PCBs) into electronics projects is not just a trend; it’s a strategic move towards cost efficiency. Custom PCBs allow designers and engineers to tailor their boards specifically to the requirements of their projects, which means reducing waste material and minimizing excess components that would otherwise drive up production costs. By optimizing layouts and integrating multiple functionalities into a single board, businesses can avoid the financial pitfalls associated with using generic or off-the-shelf solutions.

Moreover, custom PCBs can significantly reduce assembly time and labor costs. With a well-designed PCB, the complexity of wiring and connections is minimized, leading to faster production cycles. This streamlined approach not only expedites time-to-market but also allows companies to allocate resources more effectively, aligning workforce efforts with production goals. In a competitive landscape, leveraging custom PCB design can translate into substantial savings and a greater return on investment, making it an essential consideration for any serious electronics project.

Cost Efficiency of Custom PCBs in Electronics Projects

Innovation Drivers: The Impact of PCBs on Emerging Tech like IoT and AI

The role of printed circuit boards (PCBs) in driving innovation in emerging technologies such as the Internet of Things (IoT) and artificial intelligence (AI) cannot be overstated. As these fields evolve, the necessity for advanced, reliable PCBs becomes critical. The integration of IoT devices demands highly efficient, densely packed circuitry, allowing for rapid data transmission and processing. This evolution is particularly evident in smart home devices and wearable technology, where PCBs must not only be compact but also capable of handling complex functionalities seamlessly.

Moreover, the automotive industry is experiencing a revolutionary shift fueled by innovations in AI and semiconductor technology. As vehicles become increasingly connected and autonomous, the dependency on sophisticated PCBs grows. These printed circuit boards play a vital role in enabling the integration of advanced systems that enhance navigation, safety, and overall user experience. The collaboration between PCB manufacturers and tech startups is further propelling this momentum, ensuring that the automotive sector remains at the forefront of technological advancement while meeting the demands of the future.

Related Posts

-

Top 5 Insights for Successful PCB Production in Modern Electronics

-

7 Essential Tips for Sourcing the Best PCB Production Worldwide

-

Unlocking the Future of Electronics: The Essential Guide to PCB Production Innovations

-

Discover the Excellence of Best PCB Make from Top Quality Manufacturers in China

-

Solutions for Sourcing the Best PCB Circuit Boards Globally: Your Comprehensive Guide

-

Embracing Innovation: The Future of PCB Printed Circuit Board Technology and Applications