Blog

Exploring the Future of Electronics: The Role of Prototype PCB Boards in Innovative Design

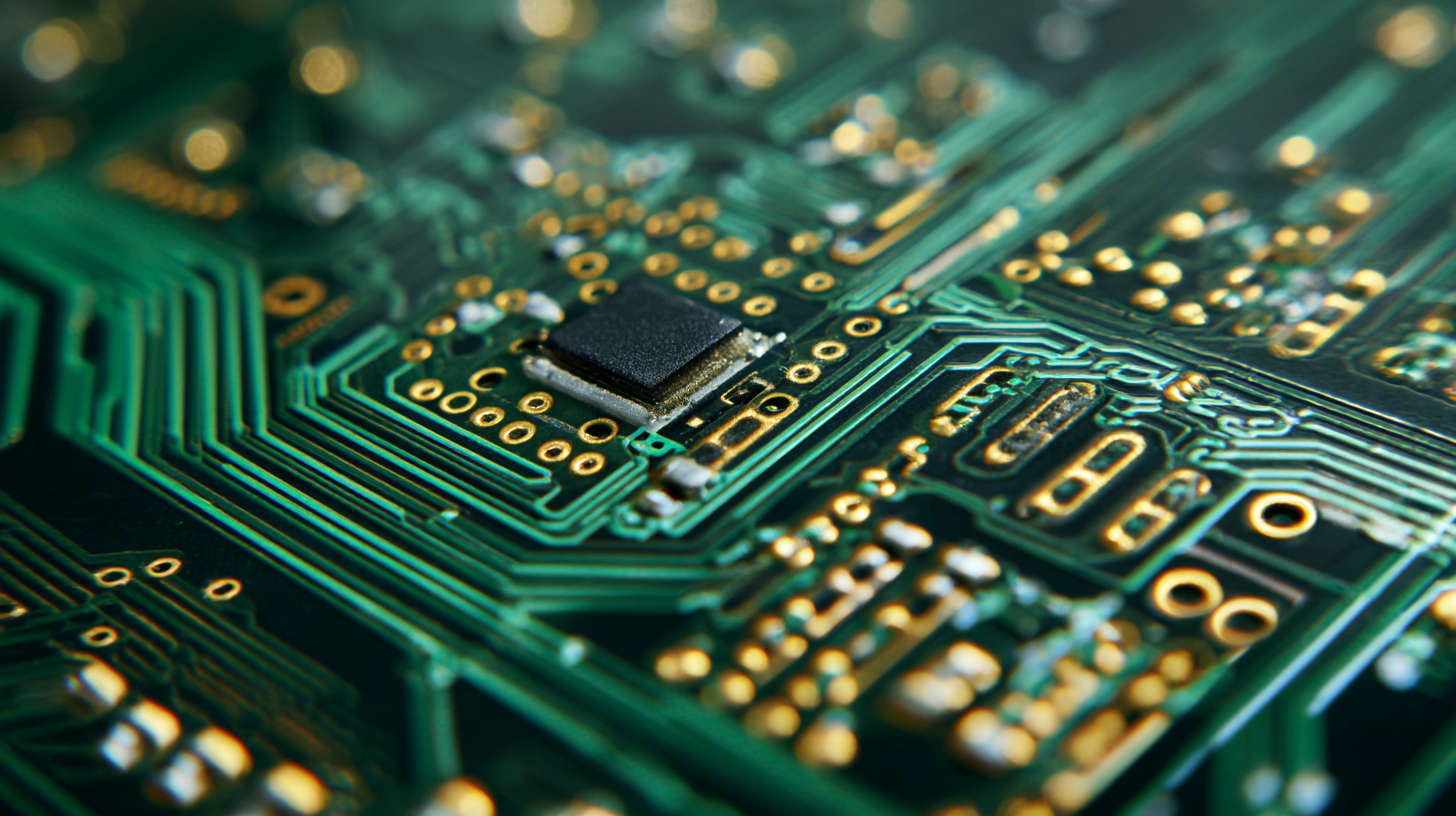

The rapid evolution of electronics design has ushered in a new era of innovation, heavily reliant on the capabilities provided by prototype PCB boards. As per the recent report by MarketsandMarkets, the PCB market is projected to reach $81.6 billion by 2026, with a significant portion attributable to the increasing demand for prototype PCBs that facilitate faster product development cycles. These prototype PCB boards serve as a critical tool for designers and engineers, enabling them to test and validate their concepts quickly, ultimately reducing time-to-market for new products.

With advancements in technology such as AI and IoT driving the demand for more sophisticated electronic solutions, the role of prototype boards in streamlining the design process is more crucial than ever. Consequently, understanding the intricacies of prototype PCB boards is essential for stakeholders aiming to stay competitive in an increasingly fast-paced industry landscape.

The Growing Demand for Prototype PCB Boards in Electronic Innovations

The demand for prototype PCB boards has surged in recent years, driven by the rapid pace of electronic innovations across various industries. As new technologies emerge, the need for efficient and effective design processes becomes crucial.

Prototype PCB boards play an essential role in this landscape, allowing engineers and designers to test, iterate, and refine their electronic concepts before mass production. This flexibility ensures that products meet market needs and quality standards while minimizing costs associated with manufacturing errors.

Prototype PCB boards play an essential role in this landscape, allowing engineers and designers to test, iterate, and refine their electronic concepts before mass production. This flexibility ensures that products meet market needs and quality standards while minimizing costs associated with manufacturing errors.

Tips for successfully utilizing prototype PCB boards include maintaining clear communication among team members during the design phase. Establish a well-defined set of specifications to avoid misunderstandings later in the process. Additionally, consider leveraging advanced simulation software to identify potential issues early on, which can save time and resources in the long run.

Moreover, it's vital to select a reliable PCB manufacturer that understands the demands of rapid prototyping. Look for partners who offer a range of materials and technologies, as these can significantly influence the performance and feasibility of your final product. By harnessing the capabilities of prototype PCB boards effectively, designers can pave the way for innovative electronic solutions that meet the needs of an increasingly tech-savvy market.

Impact of Rapid Prototyping on Design Efficiency and Time-to-Market

The landscape of product design is rapidly evolving, with rapid prototyping emerging as a crucial factor in enhancing efficiency and reducing time-to-market. The prototyping market is projected to reach USD 15.22 billion by 2032, driven by innovations in manufacturing processes and the necessity for quicker development cycles. Tools like tool-less origami manufacturing systems exemplify how advanced technologies can streamline prototyping. By enabling quick alterations and iterations, these systems help designers transform concepts into market-ready products swiftly, making them invaluable for startups and established companies alike.

In sectors such as medical device manufacturing, rapid prototyping is particularly transformative. The traditional timelines involving complex designs and extensive testing are being drastically reduced with the integration of 3D printing technologies. This shift not only lowers costs but also enhances the precision and adaptability of prototypes. As a result, the ability to deploy new medical solutions effectively positions rapid prototyping as a linchpin in the future of electronics and beyond, where timely innovation can lead to substantial competitive advantages in the marketplace.

Key Trends in PCB Technology Advancements for Future Electronics

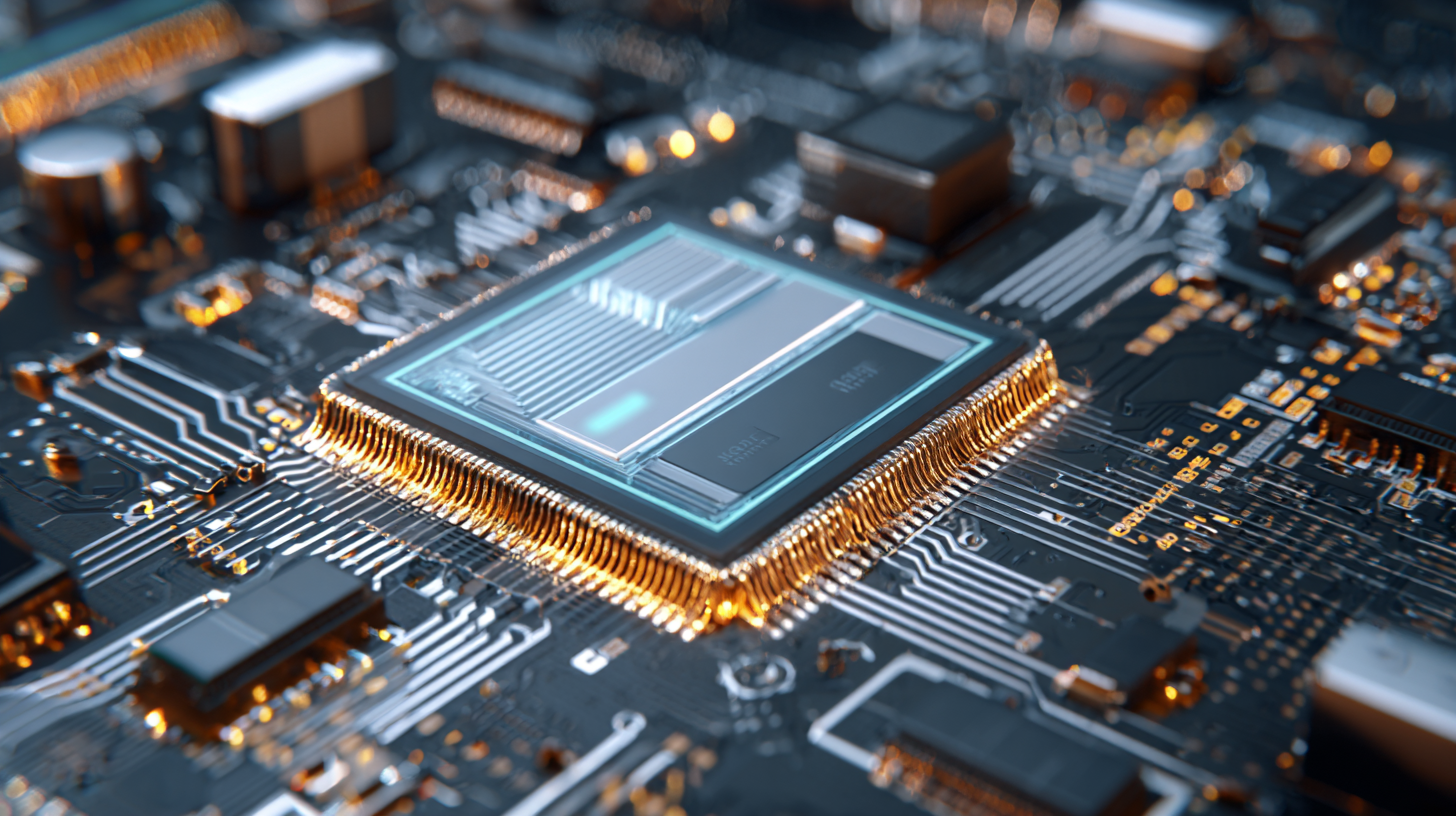

The electronics industry is undergoing a significant transformation, driven by the

miniaturization of printed circuit boards (PCBs).

As devices become smaller and more sophisticated, the demand for compact and efficient PCBs skyrockets,

leading to innovations that enhance both reliability and performance across various sectors. A recent report

highlights that the automotive PCB market alone is projected to grow from

USD 10.98 billion in 2025 to

USD 18.79 billion by 2035. This rapid growth underscores the

increasing reliance on advanced circuitry for the development of next-generation vehicles that prioritize

efficiency and safety.

Additionally, events like APEC showcase the momentum

of evolving power technologies that support innovative designs in electronics. Since its inception in

1985, APEC has highlighted advancements in power management that are crucial for emerging applications,

including artificial intelligence and green energy solutions.

With the integration of these technologies, future electronics will not only

meet the performance demands of today but will also align with sustainability goals, thus driving further

advancements in PCB technology. The ongoing trends in miniaturization and power efficiency reaffirm the

pivotal role of prototype PCB boards in shaping the future

landscape of electronics.

Case Studies: Successful Implementations of Prototype PCBs in Major Industries

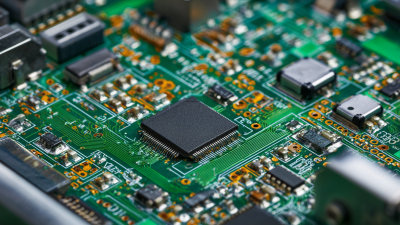

In the fast-evolving landscape of electronics, the implementation of prototype printed circuit boards (PCBs) has emerged as a critical enabler for innovative design across various industries. For instance, the medical sector has successfully incorporated prototype PCBs in the development of advanced diagnostic equipment. A study by MarketsandMarkets predicts that the PCB market will reach $80 billion by 2025, highlighting the growing importance of rapid prototyping in the design cycle. Companies leveraging prototype PCBs can reduce their production time by up to 30%, accelerating the time-to-market for crucial medical devices.

In the fast-evolving landscape of electronics, the implementation of prototype printed circuit boards (PCBs) has emerged as a critical enabler for innovative design across various industries. For instance, the medical sector has successfully incorporated prototype PCBs in the development of advanced diagnostic equipment. A study by MarketsandMarkets predicts that the PCB market will reach $80 billion by 2025, highlighting the growing importance of rapid prototyping in the design cycle. Companies leveraging prototype PCBs can reduce their production time by up to 30%, accelerating the time-to-market for crucial medical devices.

In the automotive industry, manufacturers are increasingly utilizing prototype PCBs in the development of smart vehicles. According to a report by Grand View Research, the automotive electronics market is expected to grow to $300 billion by 2026. This surge is driven by the need for sophisticated onboard devices that enhance vehicle safety and efficiency. By implementing prototype PCBs, automakers can innovate more effectively, allowing for the testing of various configurations and functionalities before mass production.

Tips: When working with prototype PCBs, consider using software that simulates electrical performance under different conditions. Additionally, establish a feedback loop with engineers and designers to ensure seamless communication, which can enhance the overall design process and lead to more successful outcomes.

Sustainability Considerations: Eco-friendly PCB Alternatives and Innovations

As the electronics industry increasingly prioritizes sustainability, the development of eco-friendly printed circuit board (PCB) alternatives is gaining momentum. According to a 2022 report from the International Electronics Industry Council, the demand for sustainable materials in electronic manufacturing could rise by 15% annually over the next five years. Innovations such as biodegradable substrates and lead-free soldering processes are setting new standards in the design of prototype PCB boards, allowing engineers to create environmentally responsible products without compromising performance.

In addition to using sustainable materials, manufacturers are exploring advanced recycling techniques that can recover valuable components and materials from discarded PCBs. A study published by the Electronics TakeBack Coalition revealed that proper recycling of electronics could potentially recover up to 50% of the precious metals used in PCB production. These innovations not only address environmental concerns but also present cost-saving opportunities for businesses looking to reduce their carbon footprint while maintaining competitive advantage in a rapidly evolving market. As the field of electronics design continues to innovate, the integration of sustainability into PCB development will play a crucial role in shaping the future of the industry.

Exploring the Future of Electronics: The Role of Prototype PCB Boards in Innovative Design - Sustainability Considerations: Eco-friendly PCB Alternatives and Innovations

| Aspect | Traditional PCB | Eco-friendly PCB Alternatives | Innovation Notes |

|---|---|---|---|

| Materials Used | FR-4 (glass epoxy) | Biodegradable polymers, recycled paper | Development of biodegradable substrates |

| Manufacturing Process | Chemical etching | Laser cutting, additive manufacturing | Increased use of 3D printing technology |

| Environmental Impact | High waste generation, chemical pollution | Lower carbon footprint, reduced toxins | Focus on circular economy |

| Performance | Standard electrical performance | Potentially lower thermal stability | Research into preservation of performance in green materials |

| Cost | Lower initial costs | Higher production costs | Long-term savings through sustainability |

Related Posts

-

Understanding the Industry Standards Challenges for Best PCB Circuit Production

-

How to Choose the Best PCB Board for Your Project Needs

-

Unlocking Quality: Proven Strategies to Source the Best Prototype PCB Board Suppliers Worldwide

-

How to Choose the Best PCB Make for Your Project Success

-

The Definitive Ultimate Guide to Sourcing and Using Flex Circuits for Global Buyers

-

How to Achieve Fast and Cost-Effective PCB Prototyping for Your Product Development