Blog

How to Choose the Best PCB Make for Your Project Success

Choosing the right PCB make is crucial for the success of any electronic project, as it directly impacts performance, reliability, and cost-effectiveness. According to a recent industry report by IPC, the global PCB market is expected to reach $82 billion by 2026, demonstrating the growing importance of selecting the right materials and technologies in this sector.

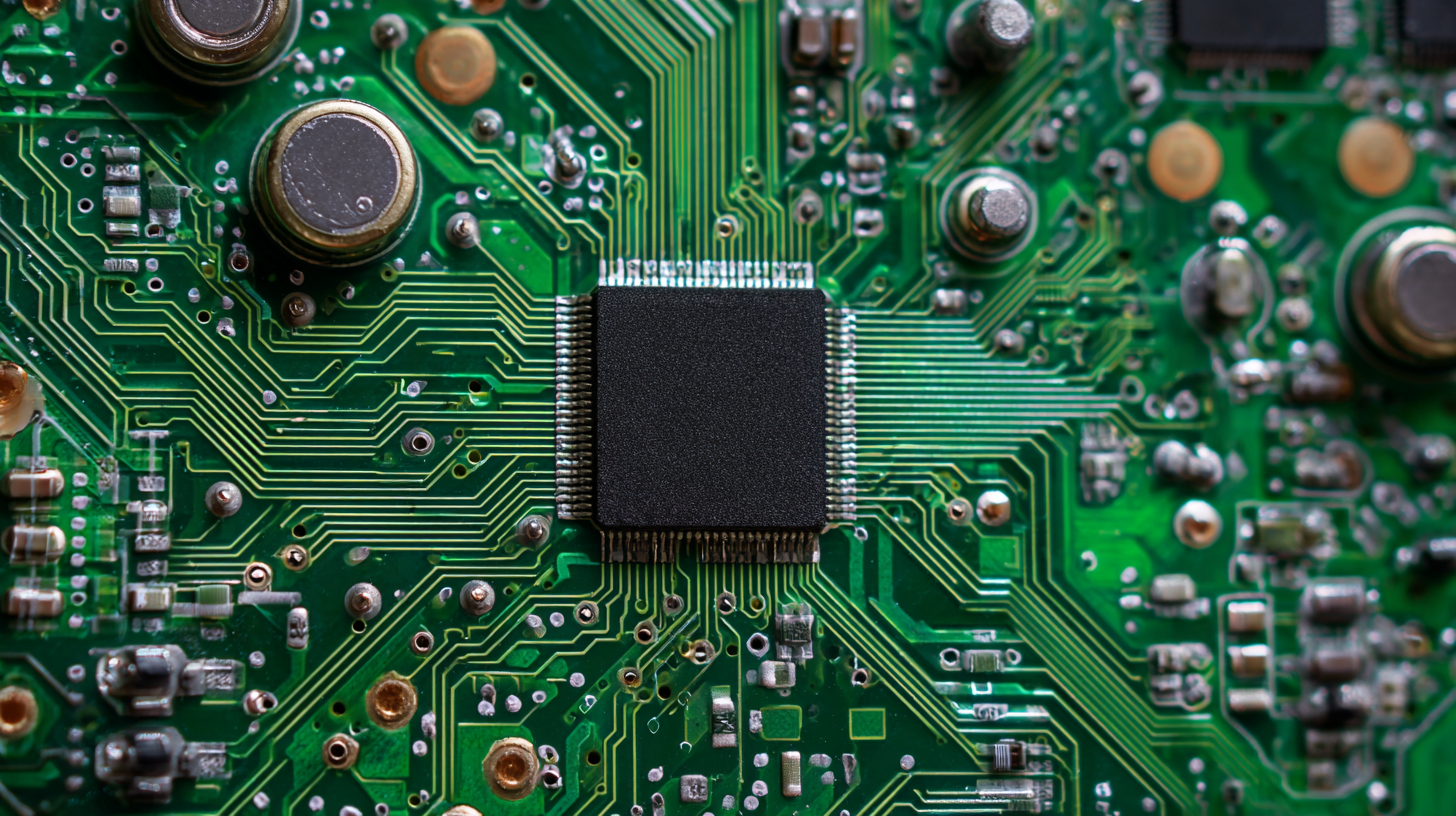

Different types of PCB make, including rigid, flexible, and rigid-flex boards, offer distinct advantages tailored to specific applications. For instance, flexible PCBs are increasingly preferred in wearable technology due to their lightweight and adaptable nature, while rigid boards remain integral in traditional electronics due to their durability.

Understanding these characteristics and their suitable applications can significantly enhance product design, reduce manufacturing challenges, and ultimately lead to project success in the competitive electronics market.

Understanding Different Types of PCBs and Their Applications

The printed circuit board (PCB) market is experiencing significant growth, driven by diverse applications across various sectors. In 2023, the global PCB market is projected to reach approximately $78.34 billion, with anticipated growth to about $88 billion in 2024, and further to $96.8 billion by 2025. The demand is fueled by innovations in automotive, consumer electronics, and telecommunications, with automotive PCBs showing a particularly promising trajectory. The global automotive PCB market is expected to expand from $9.15 billion in 2023 to $15.1 billion by 2032, reflecting a compound annual growth rate (CAGR) of 5.9% during this period.

Specialized PCBs, such as two-layer flexible copper-clad laminates (2L-FCCL), are also witnessing substantial demand. The market for 2L-FCCL was valued at $350 million in 2022 and is projected to grow at a CAGR of 6.6% to reach new heights by 2030. This growth is largely driven by the increasing integration of advanced technologies in sectors such as medical devices and wearable technology. Moreover, the rise of electric vehicles is contributing to the demand for high-performance PCBs, with the global electric vehicle relay market expected to explode from $5.34 billion in 2023 to $12.45 billion by 2030. This landscape suggests a robust future for PCB applications, highlighting the necessity for manufacturers to innovate and adapt their offerings accordingly.

Comparison of Different Types of PCBs Used in Various Applications

This chart illustrates the comparison of different types of PCBs and the number of applications they are used for. Single-sided PCBs are commonly used in simpler applications, while multi-layer PCBs find extensive applications in complex circuits.

Key Factors to Consider When Choosing PCB Materials

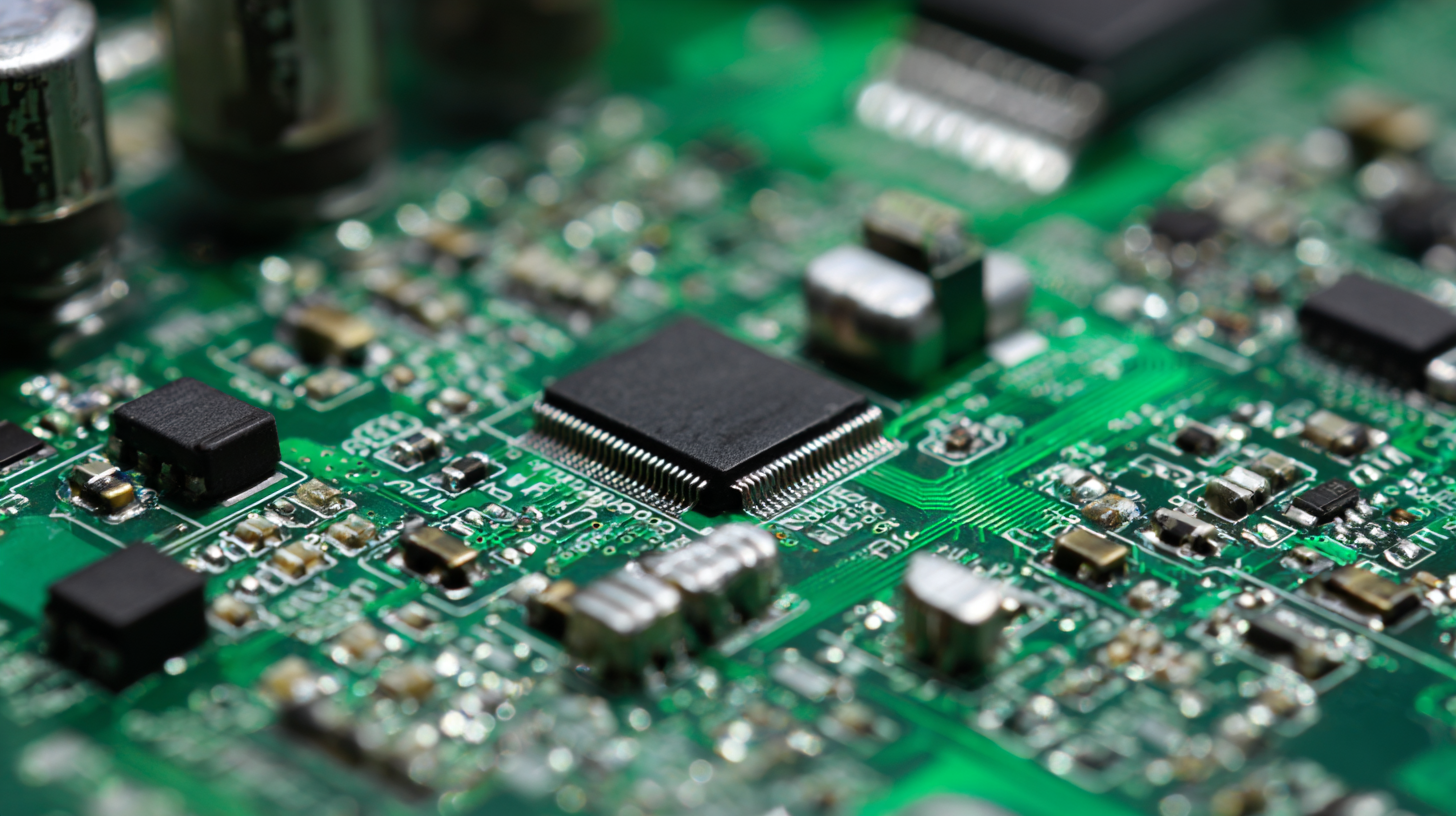

When selecting the best PCB materials for your project, understanding the key factors that influence your choice is essential. The rapid growth of industries such as automotive and electronics highlights the importance of choosing the right materials to enhance performance and meet increasing demands. Key considerations include substrate material, dielectric properties, and thermal management capabilities. Materials like liquid crystal polymers, known for their low loss and high-temperature stability, are gaining traction in high-performance applications.

Moreover, as the complexity of designs rises with the advent of AI and advanced electronic devices, the need for high-speed PCB production becomes critical. Ensuring low signal loss and optimizing electrical performance are paramount when making your selection. Additionally, considering factors such as the PCB's end use, production volume, and cost-effectiveness will significantly impact project success. In this evolving landscape, a well-informed choice of PCB materials not only supports project requirements but also drives innovation in next-generation technology.

Comparative Analysis of Conventional vs. Flexible PCBs

When it comes to selecting the best printed circuit board (PCB) for your project, the choice between conventional and flexible PCBs can significantly impact your design's performance and reliability. Conventional PCBs, made from rigid materials, offer durability and robustness, making them ideal for applications where environmental factors remain constant. They are commonly used in automotive, industrial, and consumer electronics where sturdiness and heat resistance are crucial. However, the rigidity can limit design flexibility, especially in compact or curved spaces.

On the other hand, flexible PCBs provide an innovative solution for modern electronic devices that require a lightweight and adaptable layout. Their ability to bend and conform to various shapes enables designers to create slimmer devices without sacrificing performance. Flexible PCBs are particularly advantageous in wearable technology and mobile devices, where space-saving designs are paramount. However, they generally come with higher production costs and may have limitations in terms of soldering and component placement. Understanding these differences is essential for engineers to optimize their projects and select the right type of PCB that aligns with their design goals and environmental requirements.

Impact of PCB Design Complexity on Project Costs and Timelines

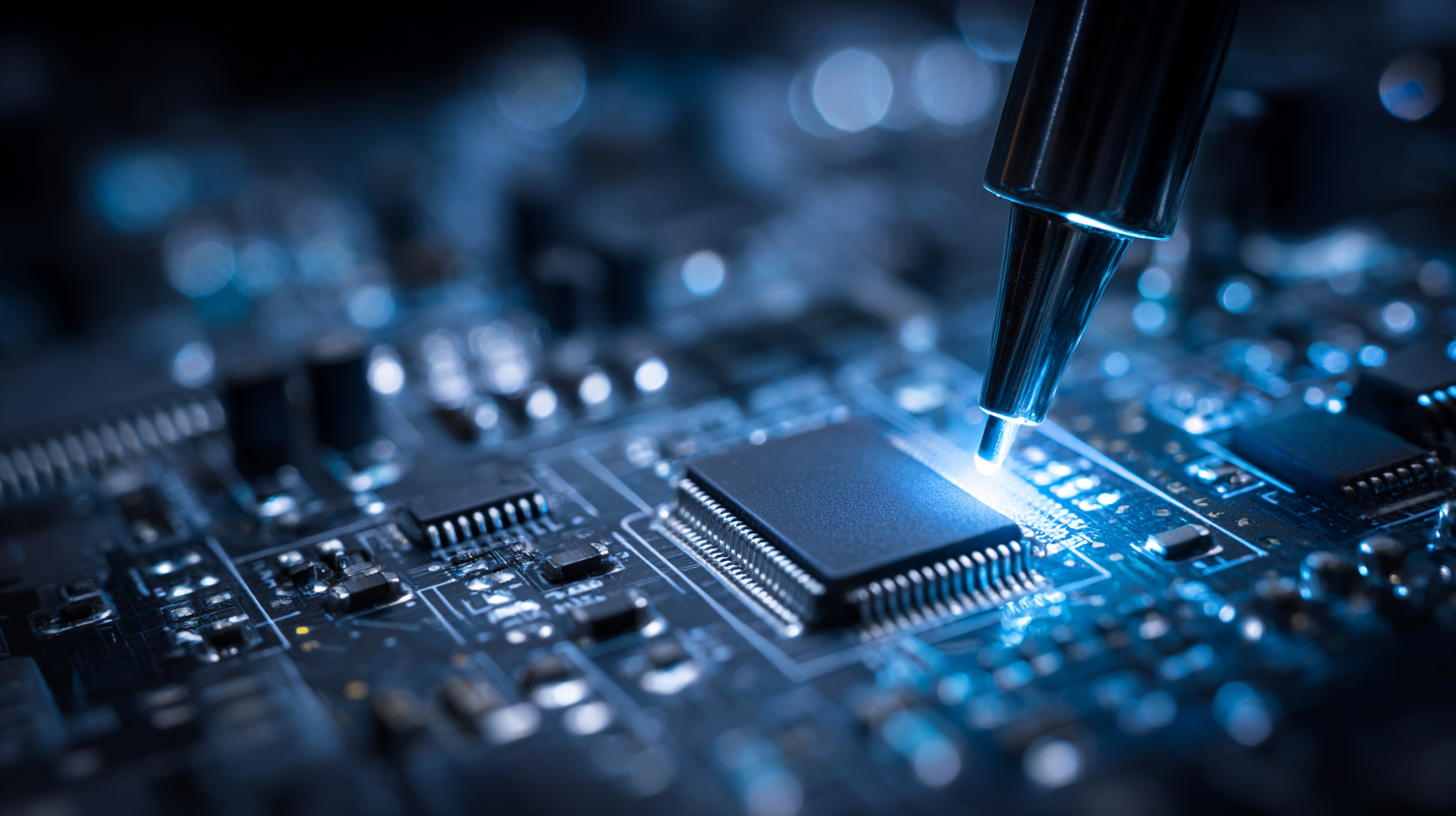

As we delve into the world of PCB (printed circuit board) design, the complexity of a project's PCB can significantly influence both its costs and timelines. Advanced designs often require more intricate layouts and higher precision in manufacturing, which can lead to increased material and labor expenses. Moreover, as electronic products evolve to become more complex and sophisticated, the need for robust design processes escalates. Companies now face the challenge of balancing the demand for highly functional PCBs with the imperative to keep costs low and shorten time-to-market.

In this context, the impact of design complexity extends beyond just the financial aspect. With the proliferation of independent engineers and digital tools, there's a growing need for streamlined processes and innovative solutions. Technologies such as AI-driven design tools are redefining the landscape, enabling faster iterations and enhanced collaboration when creating more complex PCBs. As we anticipate advancements in EDA (electronic design automation) solutions, project teams can be better equipped to handle the dual pressures of optimizing performance while managing budgets and schedules effectively.

How to Choose the Best PCB Make for Your Project Success - Impact of PCB Design Complexity on Project Costs and Timelines

| Project Complexity | Estimated Cost (USD) | Estimated Timeline (Weeks) | Recommended PCB Type |

|---|---|---|---|

| Low Complexity | 500 - 1,000 | 2 - 4 | Single Layer PCB |

| Medium Complexity | 1,000 - 2,500 | 4 - 8 | Multi-layer PCB |

| High Complexity | 2,500 - 5,000 | 8 - 12 | High-Frequency PCB |

| Very High Complexity | 5,000+ | 12+ | Specialized PCB |

Emerging Trends in PCB Manufacturing and Their Implications

Emerging trends in PCB manufacturing are reshaping how engineers and designers approach their projects, influencing everything from production efficiency to component integration. One significant trend is the rise of automation in PCB assembly, which has been reported to increase production volume by up to 30% while reducing human error. A study by IPC (Institute for Interconnecting and Packaging Electronic Circuits) highlighted that automation not only speeds up manufacturing but also enhances consistency in quality, allowing for more reliable end products.

Additionally, the growing emphasis on sustainability in the electronics sector is prompting PCB manufacturers to adopt eco-friendly materials and practices. According to a report by ResearchAndMarkets, the global green PCB market is projected to reach $13.3 billion by 2025, driven by rising environmental regulations and consumer demand for sustainable products. This shift not only helps in reducing the environmental impact but also opens avenues for companies to innovate with new materials, such as biodegradable laminates and lead-free solder, thereby aligning with global sustainability goals. As these trends continue to evolve, they will undoubtedly influence project outcomes and the future of electronic design.