Blog

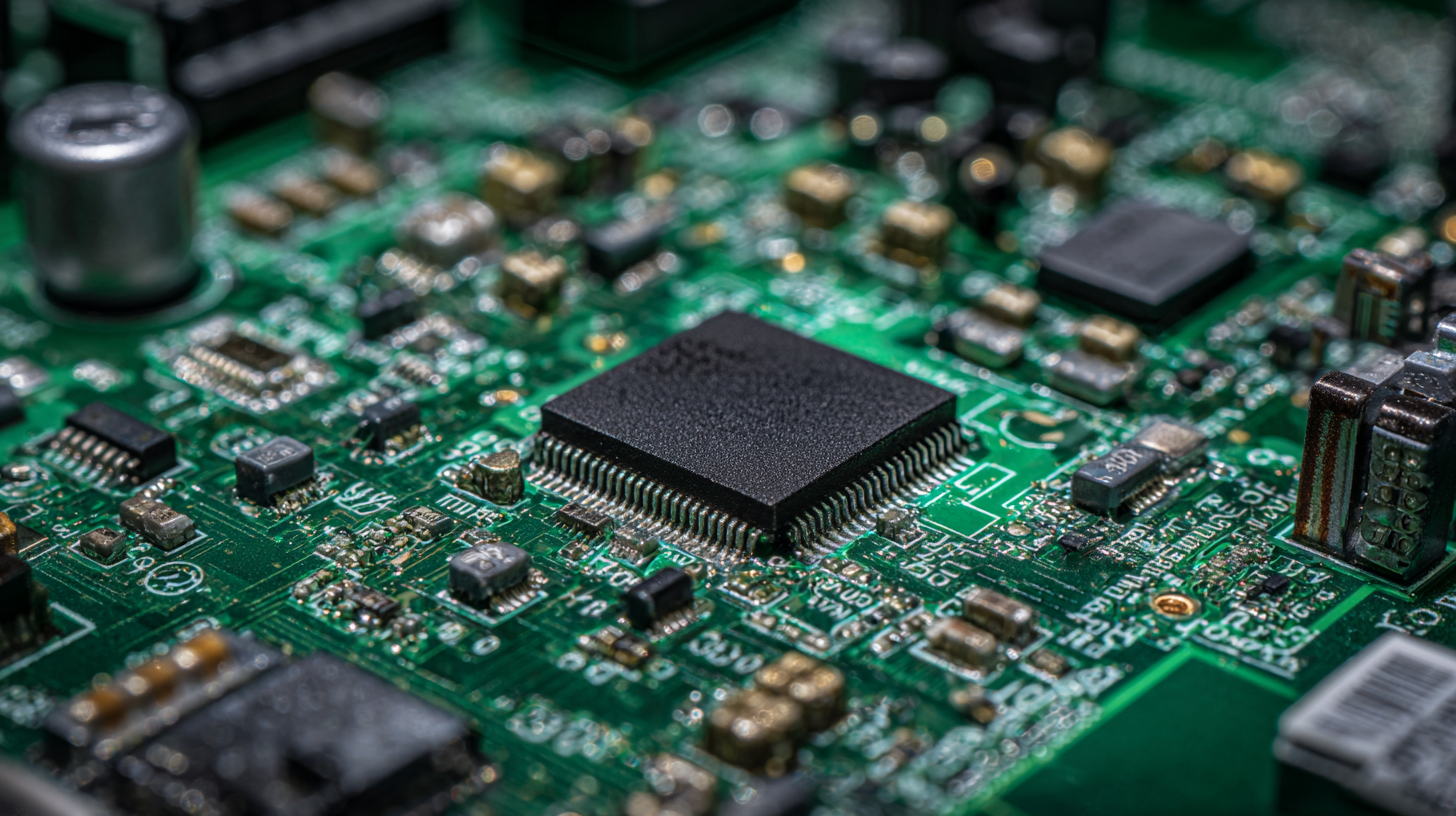

How to Choose the Best PCB Board for Your Project Needs

In the rapidly evolving landscape of electronics, the choice of a PCB board plays a critical role in the success of any project. According to a recent report by IPC, the global PCB market is projected to reach $100 billion by 2024, highlighting the increasing demand for high-quality printed circuit boards across various industries. Whether you are developing consumer electronics or advanced industrial systems, understanding the intricacies of PCB selection is essential. Factors such as after-sales service advantages and repair costs must be carefully considered, as they significantly influence the overall project lifecycle and budget. Additionally, integrating tips from industry experts can streamline the selection process, ensuring that your chosen PCB board meets all technical and financial requirements. As we delve deeper into the selection process, this guide will help you make informed decisions tailored to your specific project needs.

Understanding Different Types of PCB Technologies for Project Suitability

When selecting the best PCB board for your project needs, it's crucial to understand the different types of PCB technologies available. According to a recent industry report, the global PCB market is projected to reach $85 billion by 2027, with a significant share attributed to advanced types like rigid-flex and high-frequency PCBs. Rigid PCBs remain the most common, ideal for straightforward applications where stability and durability are priorities. On the other hand, flexible PCBs offer unique advantages for compact designs, allowing for flexibility in assembly and heightened performance in dynamic environments.

High-frequency PCBs, which cater to the demands of 5G and radio frequency applications, are gaining rapid popularity among engineers. A survey from IPC found that approximately 60% of electronics manufacturers are integrating high-frequency technology into their designs, reflecting the increasing need for effective signal integrity and reduced electromagnetic interference. Moreover, eco-friendly PCBs are becoming an essential consideration, as environmental regulations tighten. Choosing a PCB that aligns with both technical requirements and sustainability goals is vital for modern engineering projects. Each technology offers distinct advantages, making it essential to critically evaluate your project's specific needs against these emerging trends.

Key Factors to Consider When Selecting PCB Materials for Durability

When selecting PCB materials for durability, it's essential to consider various factors that can impact the longevity and performance of your printed circuit boards. One key aspect is the environmental conditions in which the PCB will operate. For instance, if the board will be exposed to high humidity or temperature fluctuations, choosing materials like FR-4 with industrial-grade specifications can enhance its resilience.

Tip: Always review the thermal and moisture absorption ratings of the materials to ensure they can withstand your project's specific conditions.

Tip: Conduct stress tests or simulations based on your application to predict how your chosen materials will hold up under real-world conditions.

By paying attention to these factors and selecting the appropriate materials, you can significantly enhance the durability and reliability of your PCBs, ensuring they meet your project needs effectively.

Analysis of Layer Count and Its Impact on PCB Performance and Complexity

When selecting a PCB for your project, the layer count is a critical factor that directly influences performance and complexity. A report from IPC estimates that PCBs with four to six layers account for approximately 60% of the global market, indicating a strong trend toward multilayer boards for enhancing functionality. With each additional layer, designers can increase routing density and reduce electromagnetic interference (EMI), which is paramount for high-frequency applications. For instance, a four-layer board typically allows for better grounding and power distribution, essential for modern, compact technology.

When selecting a PCB for your project, the layer count is a critical factor that directly influences performance and complexity. A report from IPC estimates that PCBs with four to six layers account for approximately 60% of the global market, indicating a strong trend toward multilayer boards for enhancing functionality. With each additional layer, designers can increase routing density and reduce electromagnetic interference (EMI), which is paramount for high-frequency applications. For instance, a four-layer board typically allows for better grounding and power distribution, essential for modern, compact technology.

Moreover, the complexity of the design generally escalates with a higher layer count. Research highlights that while a two-layer PCB may suffice for simple applications like basic consumer electronics, a move to an eight-layer design can support advanced technologies, such as RF communication and high-speed data transfer. As a result, many companies are leaning towards the use of high-layer count PCBs, even when the project scope may initially suggest simplicity. Ultimately, the decision on layer count must be balanced with cost and manufacturing capabilities, as the price per board increases alongside the complexity of multilayer designs.

Evaluating PCB Manufacturer Capabilities and Quality Assurance Processes

When choosing the best PCB board for your project, evaluating the capabilities of your PCB manufacturer is essential. A study by IPC (Association Connecting Electronics Industries) highlights that 65% of manufacturers face challenges with meeting quality standards due to inadequate processes. Therefore, understanding the quality assurance processes that a manufacturer employs can give you significant insights into their reliability. Look for certifications such as ISO 9001 and IPC-A-610, which ensure that manufacturing practices meet international quality benchmarks.

**Tip:** Always request a detailed overview of the manufacturer's quality assurance processes and any quality metrics they monitor, such as defect rates and yield percentages. Knowing this data upfront can save you time and potential costs down the road.

Another crucial factor is the technological capabilities of the manufacturer. According to a recent report by Allied Market Research, the global PCB market size is projected to reach $83.4 billion by 2027, emphasizing the need for advanced manufacturing techniques. Assess whether the manufacturer has invested in modern equipment and technologies, such as automated inspection systems and advanced material handling, to ensure a robust production process.

**Tip:** Inquire about past projects and case studies to gauge their experience with specific types of PCBs. This will help you ascertain if they are equipped to handle your unique project requirements effectively.

PCB Board Quality Evaluation Criteria

Cost vs. Performance: Making Informed Decisions for Your PCB Budget

When it comes to selecting the best PCB board for your project, striking the right balance between cost and performance is crucial. Understanding your specific requirements can help you make informed decisions that align with your budget constraints. For instance, if your project demands high-speed functionality and durability, investing in a more premium PCB option could save you from potential issues down the line. Conversely, if you're working on a low-stakes prototype, exploring budget-friendly options might be the way to go.

Tips: Always evaluate the required specifications—such as the number of layers, material type, and board thickness—against the intended application. This way, you can prioritize features that truly matter for your project's success without overspending on unnecessary capabilities. Additionally, consider the long-term implications: while a cheaper PCB may seem appealing, it could lead to higher maintenance costs or even project failures if it cannot handle the demands of your application.

Ultimately, integrating cost considerations with performance evaluations allows you to make smarter decisions regarding PCB board selections, ensuring that your project achieves its goals while staying within budget.