Blog

Top 5 Benefits of Using Flexible Printed Circuits in Modern Electronics

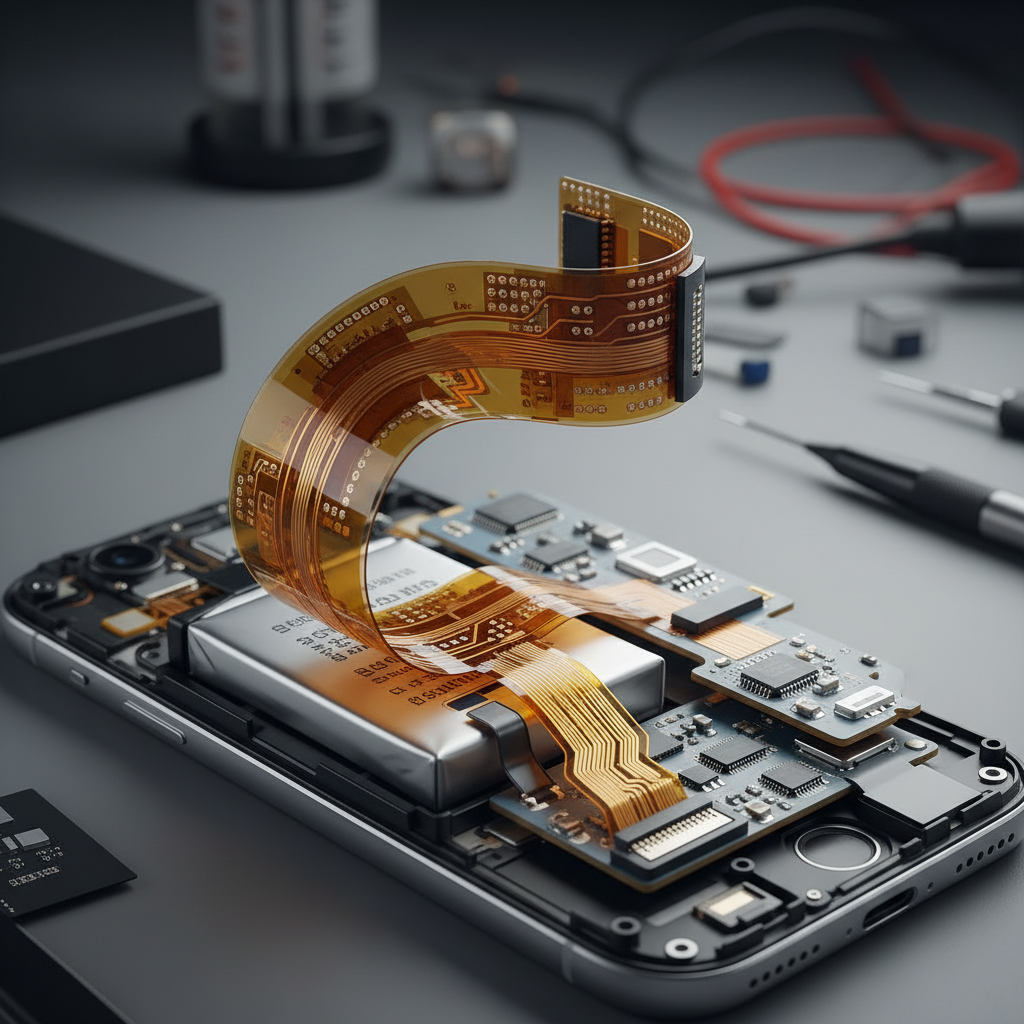

In today's fast-paced technological landscape, the demand for innovative and efficient electronic components is at an all-time high. One such component that has emerged as a game-changer in modern electronics is the flexible printed circuit (FPC). Unlike traditional rigid circuits, flexible printed circuits offer unique advantages that are driving their adoption across various industries, from consumer electronics to medical devices. The versatility of FPCs enables them to be designed in complex shapes and configurations, making them ideal for applications where space is limited and performance is critical.

Understanding the top benefits of using flexible printed circuits can provide valuable insights for engineers and designers looking to enhance their products' functionality and reliability. Flexible printed circuits contribute to weight reduction, improved performance, and increased design flexibility, among other advantages. This article will delve into the key benefits of flexible printed circuits, showcasing how they can streamline production processes and improve overall product efficacy. As technology continues to evolve, the integration of FPCs in electronic devices represents a crucial step towards more compact, efficient, and revolutionary designs.

Advantages of Space-Saving Design with Flexible Printed Circuits

Flexible printed circuits (FPCs) have revolutionized the design of modern electronics, particularly in how they optimize space. With their ability to be shaped and bent, FPCs allow for intricate layouts that traditional rigid circuitry cannot accommodate. This adaptability is crucial for today's miniaturized devices, where every millimeter counts. By integrating multiple components into a single flexible substrate, designers can create compact products that fit seamlessly into small spaces, reducing the overall footprint of devices.

Moreover, the lightweight nature of FPCs contributes significantly to space-saving advantages. Unlike traditional circuit boards, which can be bulky, flexible circuits enable manufacturers to design sleeker and lighter products. This is particularly beneficial in industries such as consumer electronics and wearables, where portability is vital. The ability to layer circuits on a flexible material means that manufacturers can also design curved and snug-fit electronic devices, enhancing both functionality and aesthetics while maximizing the efficiency of internal space.

Enhanced Durability and Reliability in Harsh Environments

The integration of flexible printed circuits (FPCs) in modern electronics has revolutionized how devices operate, particularly in harsh environments. One of the standout benefits of FPCs is their enhanced durability. Unlike traditional rigid circuits, FPCs can bend, twist, and conform to various shapes without risking damage. This flexibility not only makes them ideal for compact and intricate designs but also allows them to withstand significant mechanical stress and vibration, which is crucial for devices used in demanding conditions such as automotive and aerospace industries.

For those looking to maximize the benefits of flexible printed circuits, here are some tips: First, consider the material composition of your FPC. Using polyimide or polyester can significantly improve thermal resistance and overall durability. Second, pay attention to the circuit layout; optimizing the design can help distribute stress more evenly across the circuit, enhancing reliability. Lastly, choose appropriate connectors and soldering techniques to ensure that even under extreme conditions, the connections remain intact and functional.

In addition to durability, FPCs offer superior reliability in challenging environments. Their inherent design resilience means they are less susceptible to failures caused by environmental factors such as moisture, temperature changes, and physical impact. This reliability is vital for devices operating in harsh industrial settings, where downtime can lead to significant economic losses. By leveraging the advantages of flexible printed circuits, manufacturers can deliver high-performance products that stand the test of time, even in the most demanding applications.

Cost-Effectiveness of Flexible Printed Circuits in High-Volume Production

Flexible Printed Circuits (FPCs) offer significant cost-effectiveness in high-volume production environments, making them an attractive choice for modern electronics manufacturers. Unlike traditional rigid circuit boards, flexible circuits can be produced with less material waste and fewer assembly steps, which lowers overall manufacturing costs. The ability to design compact, lightweight, and highly integrated products accelerates the manufacturing process, allowing companies to maximize their output while reducing labor costs.

Moreover, FPCs are ideal for high-volume production as they can be efficiently mass-produced using automated processes. This scalability is crucial for meeting the demands of rapidly evolving technology markets where time-to-market is a critical factor. The reduced material costs combined with efficient production techniques enable manufacturers to offer competitive pricing without sacrificing quality. As a result, companies can achieve better margins while delivering innovative, flexible solutions that enhance product performance and longevity in diverse applications, from consumer electronics to medical devices.

Improved Thermal Management and Heat Dissipation Strategies

Flexible printed circuits (FPCs) have emerged as a vital component in modern electronics, particularly when it comes to thermal management and heat dissipation strategies. One of the standout benefits of using FPCs is their capacity to create highly effective thermal pathways. The flexible nature of these circuits allows for better distribution of heat away from sensitive components, reducing the risk of overheating and enhancing the overall reliability of electronic devices.

Moreover, the integration of FPCs into designs enables manufacturers to implement advanced materials that improve thermal conductivity. Materials like copper and specialized thermally conductive polymers can be strategically placed within the circuit layers. This not only aids in dissipating heat but also optimizes the performance of the device by maintaining optimal operating temperatures. Therefore, flexible printed circuits serve as a key enabler for compact designs, where efficient heat management is crucial for performance stability and longevity in a wide range of applications, from consumer electronics to aerospace systems.

Top 5 Benefits of Using Flexible Printed Circuits in Modern Electronics

| Benefit | Description | Impact on Thermal Management |

|---|---|---|

| Space-saving Design | FPCs can be bent and shaped to fit snugly in tight spaces. | Improves airflow and reduces heat accumulation. |

| Enhanced Durability | FPCs are less prone to breakage due to their flexible nature. | Helps maintain consistent thermal contact under vibration. |

| Improved Heat Dissipation | Flexible circuits can distribute heat more evenly across surfaces. | Minimizes hotspots and enhances component lifespan. |

| Lightweight Structure | FPCs are significantly lighter than traditional PCBs. | Reduces overall weight and thermal load on components. |

| Better Electrical Performance | FPCs can be designed for lower resistance and improved signal integrity. | Enhances efficiency and reduces heat generation during operation. |

Versatility in Applications: From Wearables to Aerospace Electronics

Flexible printed circuits (FPCs) have revolutionized the electronics industry by providing unparalleled versatility in applications. From wearables that track health metrics to aerospace electronics that require lightweight and space-efficient solutions, FPCs are the backbone of modern technology. Their flexibility allows them to fit into unconventional spaces and adapt to a variety of shapes, making them ideal for devices used in constrained environments, such as drones and smart glasses.

When incorporating FPCs into your designs, consider the benefits they offer in terms of performance and cost-efficiency. Tips for maximizing their potential include optimizing the layout to reduce material waste and taking advantage of their lightweight nature to enhance device portability. Additionally, ensure compatibility with manufacturing processes to minimize production delays and costs.

Moreover, the durability of FPCs makes them suitable for applications where traditional rigid circuits may fail. Their resistance to bending and flexing translates into longer-lasting products, especially in dynamic environments like automotive electronics. Always analyze the specific requirements of your project to leverage the unique properties of FPCs effectively and ensure they meet both functional and aesthetic criteria.

Top 5 Benefits of Using Flexible Printed Circuits in Modern Electronics

Related Posts

-

Understanding Rigid Flex PCBs: A Comprehensive Guide to This Hybrid Technology

-

Envisioning Tomorrow: The Rise of Best Rigid Flex PCB in Modern Electronics

-

How to Optimize Your Supply Chain with Rigid Flex Solutions for Global Sourcing

-

The Definitive Ultimate Guide to Sourcing and Using Flex Circuits for Global Buyers

-

Mastering Flexible Printed Circuits: A Comprehensive Step-by-Step Guide for Beginners

-

7 Essential Reasons Why Rigid Flex Technology Is Transforming Modern Electronics