Blog

Top 10 Advantages of Using Flex PCB in Modern Electronics Design

The advent of flexible printed circuit boards (flex PCBs) has revolutionized the landscape of modern electronics design, providing engineers with a versatile solution to tackle the challenges of increasing miniaturization and component density. According to a report by ResearchAndMarkets, the global market for flex PCBs is projected to reach USD 66.54 billion by 2026, driven by the growing demand in sectors such as consumer electronics, automotive, and medical devices. This surge highlights the essential role flex PCBs play in facilitating compact and efficient electronic systems.

Experts in the field have lauded the benefits of flex PCBs. Dr. Emily Chen, an industry-leading researcher at the Institute of Flexible Electronics, emphasizes their importance: "Flex PCBs not only enhance design flexibility but also significantly reduce the weight and space requirements of electronic devices." This adaptability allows engineers to innovate and develop sleek designs without compromising functionality. As we delve into the top ten advantages of using flex PCBs, it becomes clear that these components are not merely a trend; they are a crucial element in the evolution of electronic device capabilities and performance.

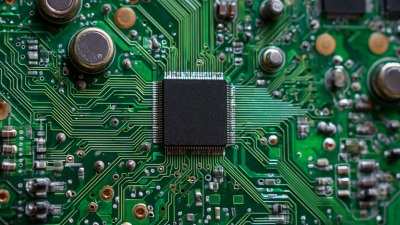

Understanding Flex PCBs: Definition and Key Characteristics

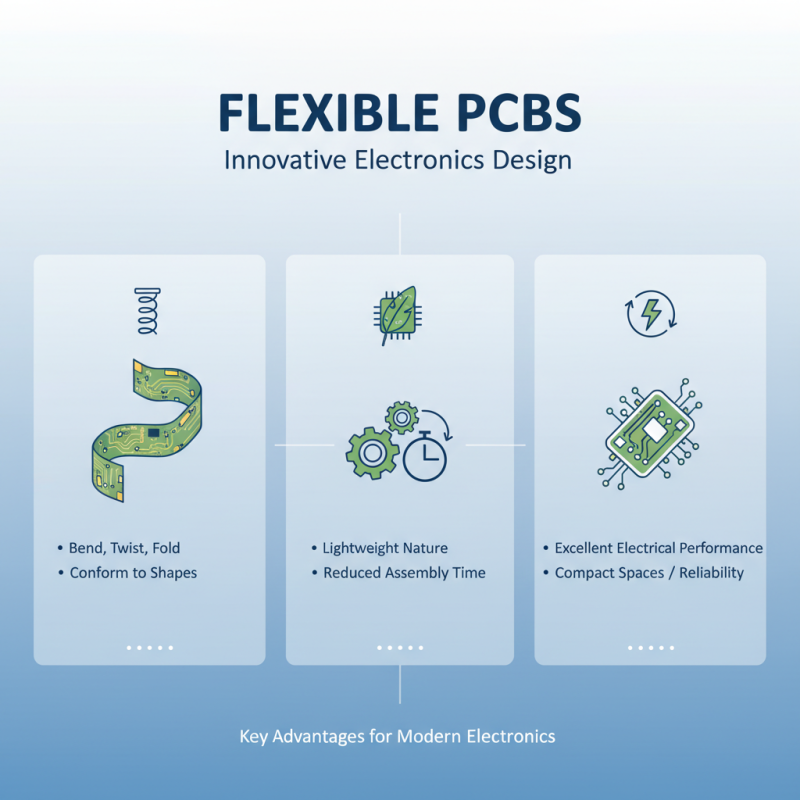

Flexible printed circuit boards, or flex PCBs, represent a significant advancement in modern electronics design. Unlike traditional rigid circuit boards, flex PCBs can bend, twist, and fold, allowing for innovative design possibilities in compact spaces. This flexibility is achieved through the use of thin substrates, which can conform to various shapes and structures. The key characteristics of flex PCBs include their lightweight nature, ability to reduce assembly time, and excellent electrical performance, making them ideal for applications where minimizing weight and maximizing reliability are crucial.

One of the standout features of flex PCBs is their ability to integrate multiple components into a single, streamlined layer. This integration reduces the number of connections needed, which in turn minimizes potential failure points and improves overall durability. Furthermore, flex PCBs are able to withstand harsh environmental conditions due to their material composition, making them suitable for use in industries such as aerospace, automotive, and healthcare. As technology continues to advance, the role of flexible PCBs in facilitating sophisticated electronic designs becomes increasingly critical, paving the way for smarter, more efficient devices.

Advantages of Flex PCBs Over Rigid PCBs in Electronics Design

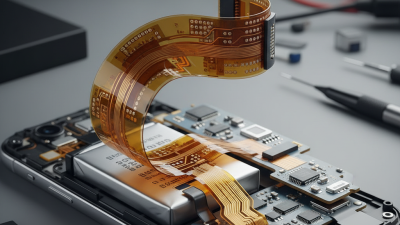

Flex PCBs offer several distinct advantages over traditional rigid PCBs in modern electronics design. One of the most significant benefits is their ability to conform and fit into compact and irregular spaces. This flexibility allows designers to create more innovative and space-efficient products, which is essential in many consumer electronics where space is at a premium. Moreover, because flex PCBs can bend and twist without breaking, they are ideal for applications that require movement, such as wearable devices and robotic systems.

Another advantage lies in their lightweight construction. Flex PCBs reduce the overall weight of electronic assemblies, which is particularly beneficial in applications like drones and mobile devices, where every gram matters. Additionally, the manufacturing processes for flex circuits can simplify assembly by reducing the number of interconnections and components required, leading to improved reliability and decreased assembly time. Furthermore, the improved thermal management capabilities of flex PCBs can enhance performance and prolong the lifespan of electronic products, making them a superior choice in many modern applications.

Top 10 Advantages of Using Flex PCB over Rigid PCB in Modern Electronics Design

Design Flexibility: The Role of Flex PCBs in Compact Circuits

In modern electronics design, the introduction of flexible printed circuit boards (Flex PCBs) has revolutionized the approach to circuit layout and functionality. The intrinsic design flexibility that Flex PCBs offer is crucial for meeting the demands of compact and intricate electronic systems. Unlike traditional rigid PCBs, Flex PCBs can be bent and shaped according to the unique contours of a device, enabling designers to optimize space without sacrificing performance. This flexibility facilitates innovative designs, allowing for greater creativity in product development where conventional circuits might fall short.

Moreover, Flex PCBs play a significant role in reducing the overall size and weight of electronic devices. In applications where space is at a premium, such as wearables or handheld gadgets, the ability to integrate components into a single, streamlined layer enhances efficiency and boosts functionality. This capability is essential in modern electronics, where miniaturization is not just a trend but a necessity. By leveraging Flex PCBs, engineers can create compact circuits that not only fit into tight spaces but also enhance the durability and reliability of the end product, making them an indispensable element in the design of contemporary electronic devices.

Enhanced Durability and Reliability of Flex PCBs in Various Environments

Flex PCBs (Printed Circuit Boards) have emerged as a game-changer in modern electronics design, particularly due to their enhanced durability and reliability across various environments. One of their main advantages lies in their ability to withstand mechanical stress and vibrations, which places them ahead of traditional rigid PCBs. This flexibility allows them to be used in devices that experience frequent movement or those that must fit into tight spaces without compromising functionality. Consequently, manufacturers are increasingly favoring flex PCBs in industries such as automotive, consumer electronics, and medical devices where resilience is essential.

**Tips for Selecting Flex PCBs:**

When considering the integration of flex PCBs into your designs, ensure that you assess the materials used, as they significantly influence durability. Choosing high-quality polyimide or other robust substrates can enhance thermal stability and resistance to environmental factors like humidity and temperature fluctuations. Additionally, designing for the specific application and environment will further improve reliability.

Beyond their physical attributes, the design capabilities of flex PCBs allow for intricate layouts and reduced overall weight in electronic devices. This feature becomes crucial in applications where weight savings lead to better performance, such as in UAVs or portable consumer gadgets. By leveraging the unique strengths of flex PCB technology, engineers can create innovative designs that meet the demands of contemporary electronics while maintaining reliability in challenging conditions.

Top 10 Advantages of Using Flex PCB in Modern Electronics Design

| Advantage | Description | Applications | Environment |

|---|---|---|---|

| Lightweight | Flex PCBs are thinner and lighter than traditional PCBs, making them ideal for portable devices. | Smartphones, Wearable Tech | Mobile Environments |

| Space Saving | Allows for complex circuitry in a compact design, optimizing space. | Consumer Electronics, Medical Devices | Tight Spaces |

| Enhanced Durability | Flex PCBs are more resistant to mechanical stress and bending. | Automotive, Aerospace | Harsh Environments |

| Design Flexibility | Can be designed in various shapes and layouts, fitting complex configurations. | Robotics, Drones | Dynamic Applications |

| Better Thermal Management | Improved heat dissipation properties compared to rigid PCBs. | High-Power Electronics | High-Temperature Environments |

| Reduced Assembly Costs | Fewer components required, resulting in lower labor and production costs. | Mass Production | Manufacturing Environments |

| Improved Electrical Performance | Shorter signal paths reduce electrical noise and improve signal integrity. | Telecommunications, Networking Equipment | Critical Communication Environments |

| Resilience to Environmental Factors | Can withstand humidity, temperature fluctuations, and other adverse conditions. | Outdoor Applications, Industrial Machinery | Extreme Conditions |

| Ease of Integration | Flexible design allows easy integration into various hardware layouts. | Custom Electronics, Prototypes | Versatile Integration |

| Customization Potential | High level of customization available to fit specific project needs. | Specialized Devices, Custom-built Circuits | Tailored Solutions |

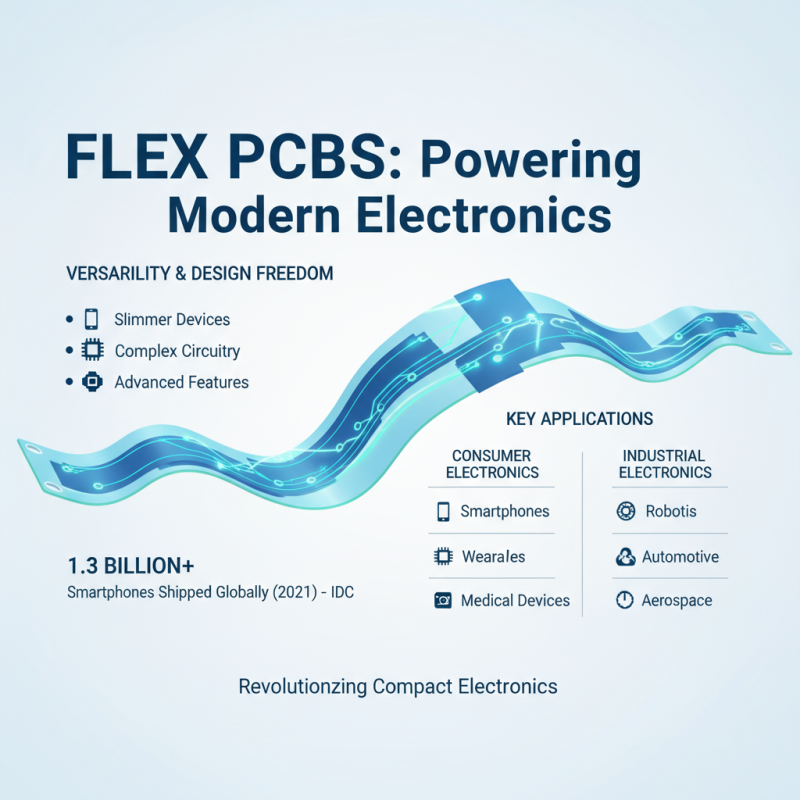

Applications of Flex PCBs in Modern Consumer and Industrial Electronics

Flex PCBs, or flexible printed circuit boards, are revolutionizing modern consumer and industrial electronics by offering unmatched versatility and design freedom. One of the key applications of flex PCBs is in the smartphone industry, which, according to the International Data Corporation (IDC), saw over 1.3 billion units shipped globally in 2021. The compact nature of flex PCBs allows manufacturers to create slimmer devices while integrating complex circuitry, enabling features like advanced cameras and faster processors without compromising on space.

In industrial electronics, flex PCBs play a significant role in the development of automation equipment and robotics. A report by Research and Markets highlights that the global robotics market is expected to reach USD 74 billion by 2026, indicating a growing demand for flexible solutions in design. The adaptability of flex PCBs allows for intricate designs that can easily conform to the unique shapes and requirements of robotic systems, leading to enhanced performance and efficiency.

**Tip:** When designing with flex PCBs, ensure that bend radii are adhered to according to manufacturer specifications to prevent damage during assembly and operation.

Another noteworthy application is in wearable technology, where the need for lightweight and flexible design is critical. As per a report by CCS Insight, the wearable tech market is projected to reach USD 116 billion by 2026. The integration of flex PCBs in devices like smartwatches and fitness trackers facilitates comfort and functionality, proving essential for consumer acceptance and satisfaction.

**Tip:** Consider using a combination of rigid and flexible circuit designs when developing new wearable technology to optimize space and enhance reliability.

Related Posts

-

Envisioning Tomorrow: The Rise of Best Rigid Flex PCB in Modern Electronics

-

Mastering Flexible Printed Circuits: A Comprehensive Step-by-Step Guide for Beginners

-

Future Trends of Flex Circuit Board at 2025 China Import and Export Fair Insights and Data

-

How to Choose the Best PCB Make for Your Project Success

-

The Definitive Ultimate Guide to Sourcing and Using Flex Circuits for Global Buyers

-

Top 5 Benefits of Using Flexible Printed Circuits in Modern Electronics